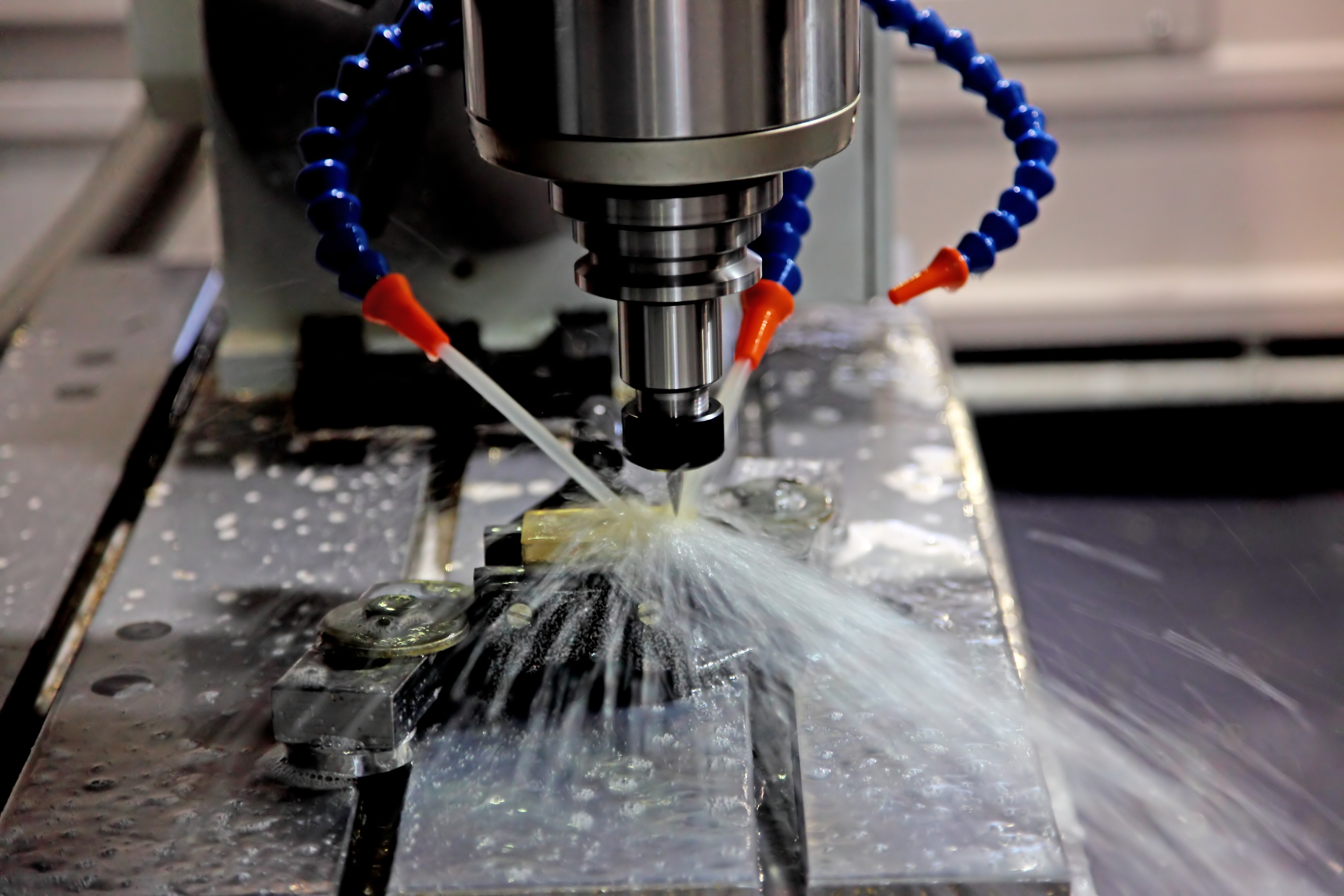

NUCOOL METALWORKING FLUIDS

The Nutech NuCool line of coolants consist of soluble oils, semi-synthetic, full synthetics and environmentally friendly alternatives. Soluble oils are formulated to provide optimum boundary lubrication and finish. They are recommended for operations where high friction is encountered. Semi-Synthetics provide boundary lubrication, good cooling characteristics and have low maintenance requirements. These moderate to heavy duty cutting fluids are recommended for grinding and machining of cast iron, steel, stainless and non-ferrous metals. Full Synthetics contain no oil offering optimum cooling and cleanliness. They are often used for grinding and light duty operations, but highly fortified versions are applicable for heavy duty machining. The NuCool environmentally friendly coolants are premium plant oil based fluids that are extremely bio-stable, low foaming, clean with excellent corrosion protection properties.

NuCool Soluble Oil Coolants

Heavy Duty Solubles: Offered in both chlorinated and non-chlorinated versions. These highly fortified clean cutting fluids are suitable for all machining operations and most high pressure systems. These bio-resistant coolants are stable in all water types and offer excellent rust protection. They have excellent film strength and improved cooling capacity. They are well suited for a variety of operations such as, broaching, tapping and boring of hard steels and nickel alloys.

NuCool 505

NuCool 2795

NuCool Semi-Synthetic Coolants

NuCool ELITE 3000 Is a unique metal working fluid that is virtually 100% bio-resistant and is a no dump metalworking fluid. It’s designed for all ferrous and most non-ferrous materials.

NuCool 3305 is an economical medium duty semi-synthetic fluid designed for most machining operations on ferrous and non-ferrous materials. Its unique blend of raw materials provides a great balance of film strength and lubrication while dissipating heat for maximum tool life. NuCool 3305 is controlled within a 7-10% concentration range and will continually inhibit corrosion, efficiently splits tramp oils while providing long running bacteria free operation.

NuCool 3311 is a high performance semi-synthetic coolant that utilizes extremely high viscosity lubricants for exceptional boundary lubrication and heat extraction resulting in improved tool life on all materials. NuCool 3311 is clean running, bio-stable, low foaming and provides exceptional corrosion protection. NuCool 3311 will extend tool life, provide excellent finish and rejects tramp oils efficiently.

NuCool 3350 is a next generation hybrid semi-synthetic designed to provide high performance in all machining operations and on all materials. NuCool 3350 provides maximum lubrication, heat dissipation and film strength characteristics for optimum tool life. This clean running fluid minimizes smoke, misting and has no reportable VOC’s. NuCool 3350 provides extremely long sump life, excellent corrosion control, resists bacteria growth and efficiently splits tramp oils.

NuCool Full Synthetic Coolants

Heavy Duty Synthetics: These synthetic fluids are designed to resist microbial degradation and provide clean clear work piece visibility. They provide an optimum balance of lubricity and detergency for quality finishes on machined parts. Special corrosion inhibitors give excellent protection against rust on parts and machine surfaces. Recommended for medium to heavy duty machining of ferrous and non-ferrous materials. The oil rejecting properties keep sumps clean and odor free.

Light & Medium Duty Synthetics: These synthetics are designed to provide excellent cooling, rust protection and work-piece visibility in very turbulent grinding applications without generating foam. Ideal for grinding carbon steels, malleable iron, cast iron and carbide. The use of bio-resistant components assures that the fluid will resist selective depletion and foul odors.

NuCool 4005:

NuCool 4010:

NuCool 4012:

NuCool 4015:

NuCool 4018:

NuCool 4050:

NuCool 4000C:

NuCool Misting Lubricant:

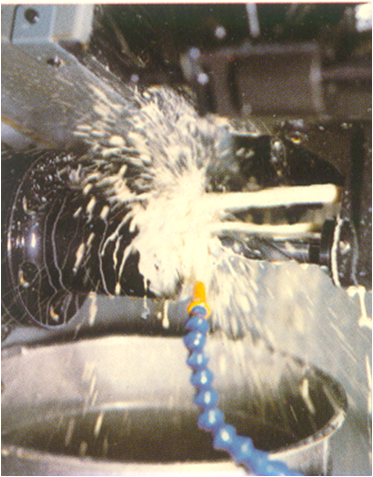

Straight Cutting Oil

Neat Oils: These oils are formulated with premium grade base oil stock. They are available in a wide variety of viscosities and EP packages. Designed for cutting, forming, rolling, honing, skiving and a variety of other metal working applications.

NuCut 20

NuCut 137

NuCut 150

NuCut 200

NuCut 262

Dual Purpose Cutting Oils: These oils exhibit outstanding lubricity for cutting difficult materials. Can be used on the lube side of most machines without diluting the cutting oils. Safe on yellow metals.

Low Viscosity Cutting Oils:These oils have outstanding lubricity for use on all steels and yellow metals.They can be used on through the tool coolant systems where heat dissipation is required to maintain size on smaller parts.

Screw Machine Oils: These highly compounded oils are designed for difficult swiss turning applications. Products are formulated with & without active sulfur and chlorine.

Gundrill Oils: These low viscosity oils are highly compounded with anti foaming and oxidative stability packages. They are capable of doing most difficult gundrilling jobs and can be used in through the tool systems.